If you require any kind of air compressors, blowers or treatment equipments for PET Bottle Blowing, then browse through the product and services provided by IRCO and be sure of world class solutions for your business.

The PET Bottle blowing industry is one that hardly ever experiences a downfall in the financial returns considering the customer usage pattern for such kinds of products do not depend much on greater economic issues. As such, the demand for newer and better kinds of PET Bottles are always on the rise and hence IRCO continue to serve the industrial requirements for bottles by coming up with improvised techniques to manufacture them, never for once forgetting the health safety issues that are equally important to be followed.

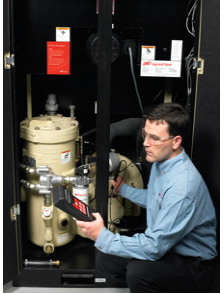

Equipments including various kinds of air compressors, air blowers and air treatment machineries are manufactured under technologically advanced methods in the world class units owned by Ingersoll Rand. With the aim of living true to their objective of providing solutions, products and services for energy efficient and eco friendly business operations, IRCO had acquired Hibon (or Hibbon) in the year 2006. At that point of time Hibon was a part of BOC Edwards. Thereafter, IRCO has constantly made efforts towards taking the quality of industrial air blowers, compressors and treatment equipments.

Here is a list of the air compressors that this organization manufactures:

- Small Reciprocating Air Compressors

- Rotary Contact-Cooled Air Compressors

- Rotary Oil-Free Air Compressors

- Centrifugal Air Compressors

- PET Blow-Molding Air Compressors

It is not just a matter of a few years that these air compressors are being manufactured and supplied to the clients. The Small Reciprocating variety, for one, is in the market for the last 80 years. So, if you are wondering about the authenticity and the market reputation of Ingersoll Rand, then this small bit of information might be enough to let doubts rest. These air compressors have been given timely technical installations in keeping with the modern day requirements. The same goes for the rotary contact-cooled air compressors.

If you are looking for an air compressor that further takes care of air contamination then the Rotary oil free air compressors are perfect for your requirements. For the business owners who are on the lookout for a world class multi stage centrifugal air compressor, IRCO provides that as well.

While using the PET Bottle blowing compressor, the PET Blow Molding air compressor, the industrial clients can be assured of certain benefits which will definitely reduce their operation cost. Apart from optimum production levels in a cost effective way, these blowing equipments also offer you with flexible configurations, which allows you to set the measurements according to the requirement.

You may also come across Hibbon (Hibon) blowers while searching through the catalogue for appropriate blowing equipment. Don’t be confused when you do! As mentioned earlier, Hibon is now a part of Ingersoll Rand and there is no reason to doubt the quality of the brand at all. To top it all, you also get to avail certain value added services such as leak management, installation, after sales service, health and safety check, breakdown cover amongst others.